loading

10HL beer brewing equipment was widely used in brewery,The whole brewing system including Grist miller,brewhouse,fermentation tank,cooling system,CIP and Controller,the equipment can be also customized.

| Availability: | |

|---|---|

Product Video

Product Description

10HL Beer Brewery Equipment

10HL microbrewery equipment is typically applied to breweries that are much smaller than large-scale corporate breweries and are independently owned. Such breweries are generally characterized by their emphasis on flavor and brewing technique. We offer a Microbrewery (mini brewery) with the productivity of 1000L (10BBL) to 5000L (50BBL) per brew. The service includes: complete set of microbrewery equipment, installation turn key, recipes and technology of branded beers, staff training and more. Microbrewery comes complete "turnkey" The performance of your Microbrewery (Brewery and mini brewery), if necessary, can be increased in the future.

Specifications

Output/Brew | 10HL |

Brew/Week | 2~6 |

Output/Week | 20~60 hl |

Electric Supply | 3phase/380(220, 415,440…)v/50 (60)Hz |

Heating Source | Electric/Steam |

Area Request | >45M2 |

Brewmaster | 1 |

Note: 1hl=100liter; 1Gallon=3.7854liter; 1Barrel (BBL) =117Liter;

Configuration

1. Malt Milling Unit

Particle adjustable rolling crusher

Flexible or steel auger to directly lift the milled grain to mash tun

2.100HL Brewhouse Unit

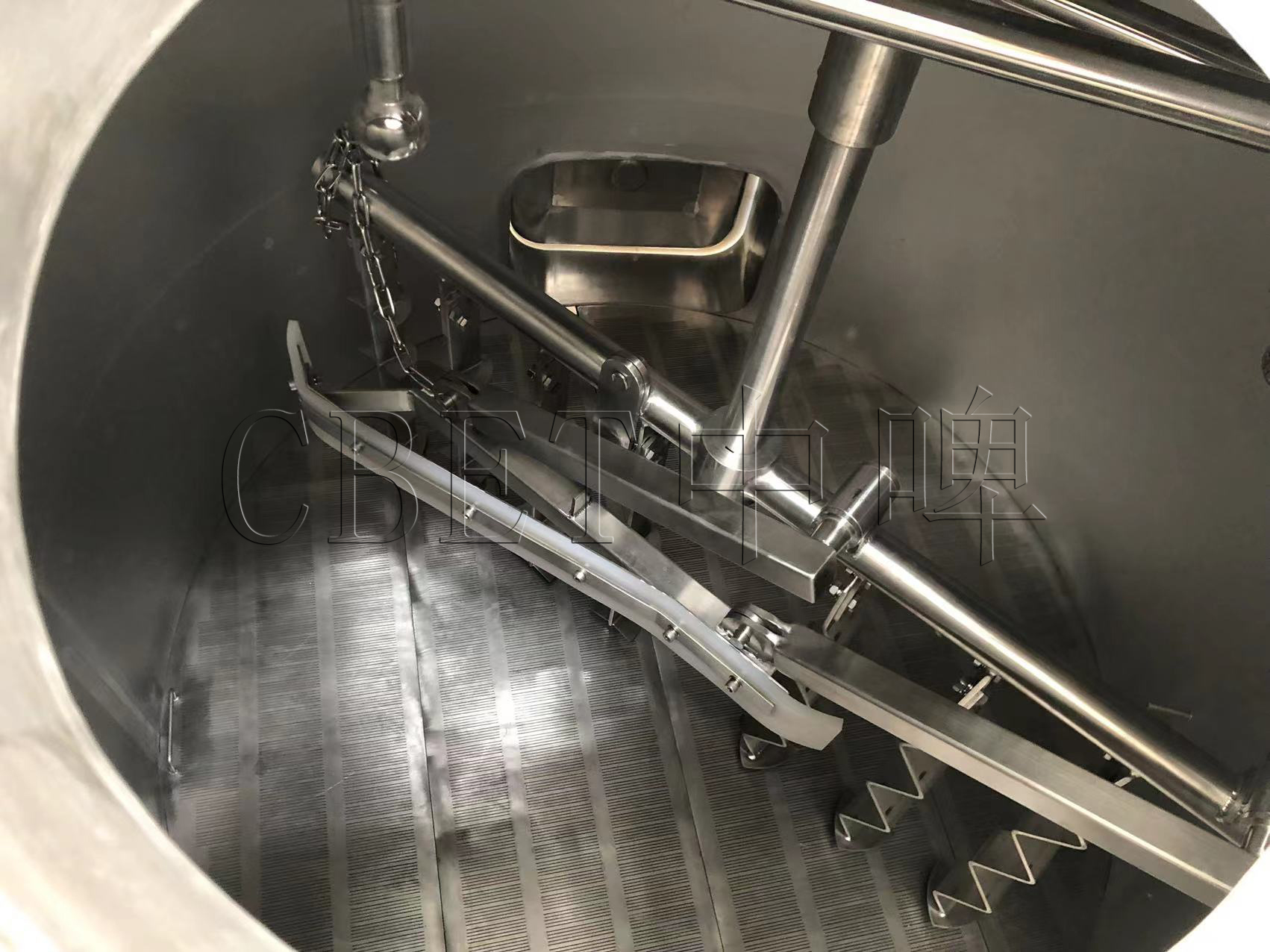

Mash tun, Lauter tun, Boiling Kettle, Whirlpool tun in various combination

Hot water tank and cold water tank for optional in special combinations

Infusion or decoction brewing methods are designed exactly

Stainless steel are popular because of easy maintenance and clean, copper cladding for optional

Two stages or single stage heat exchanger for wort cooling

Completely stainless steel integrated work platform

Sanitary and efficiency wort pump

All pipings and fittings

3.10HL or 20HL Fermentation Unit

Standard stainless steel conical cylindrical fermentation tanks

Single size or double size as brewhouse is common used in microbreweries

Tanks quantity is exactly calculated by fermentation cycle for various beers

All manhole, valves, pressure gauges, fittings etc are included 4.Beer Filter Unit

4.Beer Filter Unit

Craft beer is no need filtration which will keg filling for quickly consumption

Plate-Frame or Candle type DE (diatomite earth) filter is used for clarify the beer

5. 10HL or 20HL Bright Beer Tank Unit

Standard stainless steel bright tanks for beer maturation, conditioning, service, carbonation

Single size or double size as fermenter is common used in restaurant or bar

Tanks quantity is exactly calculated for various beers and the function

All manhole, valves, stone, gauges, fittings etc are included

6.Cooling Unit

Insulated glycol water tank with or without copper coil for glycol liquid holding and mixing

Efficiency chillers or refrigerators with freon to supply cooling energy

Sanitary centrifugal pump for glycol water recycle among tanks and heat exchanger

All pipes, fitting, insulation materials are included

7.Controlling Unit

Electrical controlling cabinet with temperature, on-off controlling for brewhouse

Electrical controlling cabinet with temperature, on-off controlling for cooling parts

Temperature controller, thermocouple, solenoid valves etc are included

PLC with touch screen panel for special request

8.Beer Dispense

Keg filling and rinsing machine

Semiauto bottling machine with rinsing, filling, capping, labeling etc

Flash pasteurizer or tunnel pasteurizer is available

9.Other Facilities

Portable or fixed CIP system for cleaning the tanks

Steam boiler for brewhouse heating

Water treatment for brew water

Oil free air compressor

Brewery lab instruments for beer quality test

Product Advantage

All Construction is from SUS 304 food grade stainless steel, all pipes are SUS304

All signs & wording in English

All tanks to be supplied with Data Plates including Test Data & Serial Number

All tanks will be tested and inspected in the NDT room after construction & Quality Control Checks

All jackets will be tested using water pressure testing, testing pressure: 0.4Mpa (4 Bar) & working pressure:0.2Mpa (2Bar)

All tanks will be pressure tested for 48hours before leaving the ZPET factory;

All the welds are full TIG welded by water spray method to ensure uniform weld pattern with full pickling & passivation

All tanks are mirror polishing inside, to be Ra 0.4um.

All Gaskets are manufactured with EPDM

Trading Terms

Payment Term:

T/T transfer, 40% advance payment in order to start production,

T/T transfer 60% before the equipment is shipped.

Alibaba trader assurance is available to guarantee your payment safety.

Delivery Term:

The manufacturing time is 30 – 45 working days, and will be commenced as soon the initial 40% deposit is received in ZPET account and technical drawings are signed & confirmed by the client

The technical files, layouts, drawings and all other technical confirmation time(s) shall not be included in the manufacturing time.

Production will not start until all drawings, technical files or layouts are confirmed & signed by appropriate party. This can lead to delays in production and / or delivery time if not completed.